- Home

- >

- Automated assembly

Robotic gluing

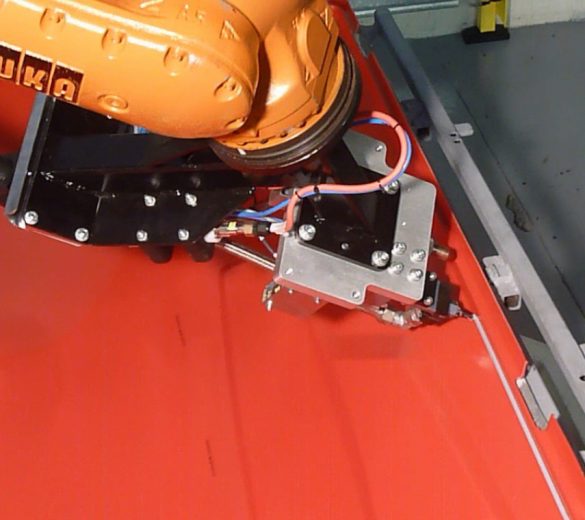

Robotic gluing – Glue robot system

Robotic gluing, or gluing in general, is a widely used industrial fastening solution, with the latest advances in adhesive technology now enabling the gluing of any type of material.

Gluing limits the number of parts needed and provides a simple, cost-effective, means of automated assembly.

There is a wide range of formulations to choose from depending on the nature of the materials to assemble, the adhesive’s stated function and the conditions of application.

For automation purposes, the choice of pumping station depends directly on the type of adhesive used (single-component, boosted single-component, two-component, etc.), the quantities involved, and so on.

GEBE2 integrates to its sealing robots pumping/dosing systems with drums ranging from 5 kg to 200 L. For small volumes, there is the option of cartridge packaging where GEBE2 offers glue robot system with compact and autonomous embedded dispensing heads.

Robotic gluing advantages

Robotization improves gluing repeatability and controls bead cross-sections.

Profitability is generated by gains in productivity, and also by optimizing adhesive consumption rates.

Examples of robotic gluing applications: window gluing, windscreen gluing, bodywork gluing