- Home

- >

- Composite and metallic finishing process

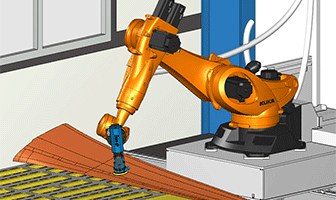

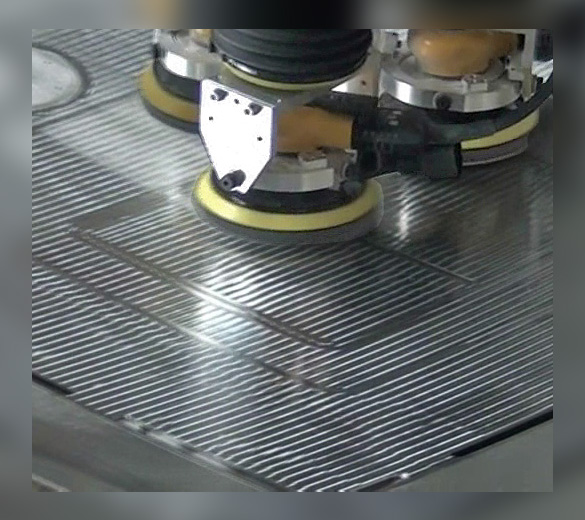

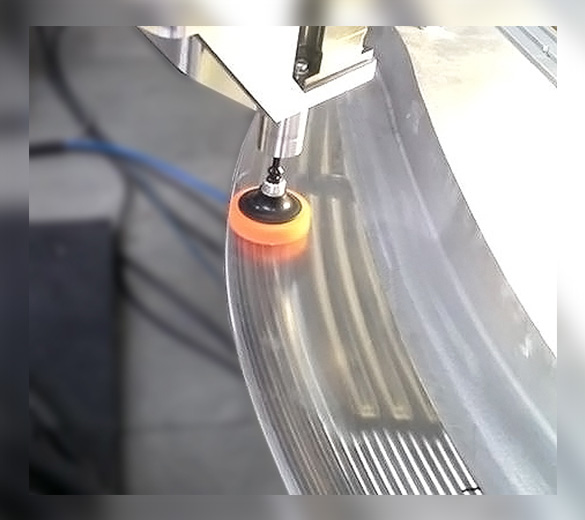

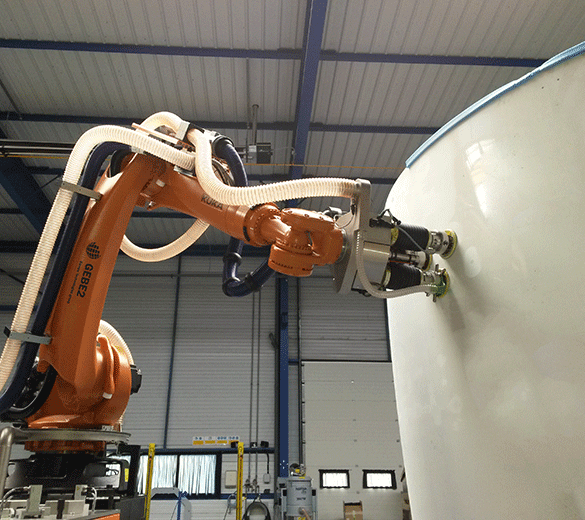

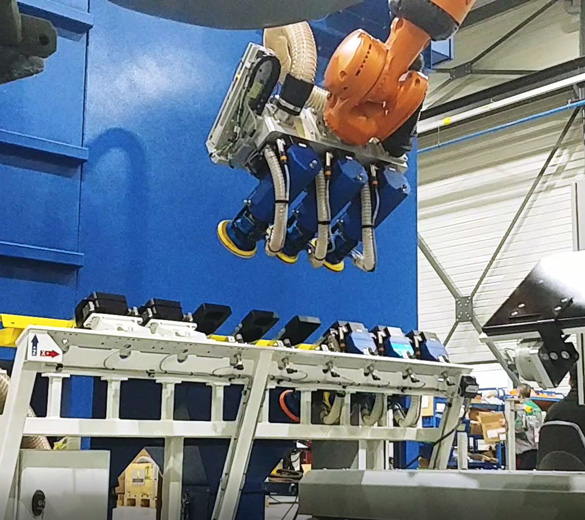

Robotic metal and composite sanding

- Society

- Robotic finishing processing

- Automated assembly

- Automated assembly

- Robotic inserts installation

- Robotic gluing

- Robotic welding cells

- Automated production line

- Our markets

- Our markets

- Aerospace

- Automotive

- Boating

- Energy & Defense

- Railway

- Space

- Technical center

- Technical center

- Industrialization and training

- Test cells and technical support

- News

- Contact

- FR

- Downloads