SECAM FIXING SOLUTIONS, provider of fixing solutions, is partnering with GEBE2 to offer a fully automated fastening solutions dedicated to honeycomb and metal sandwich panels.

Conventional fixing processes for sandwich panels (nomex and aluminum) require multiple manual operations with no guarantee regarding repeatability.

This process implies an increase of pipeline products as it requires the immobilization on production lines up to 24 hours before handling, moving and fixing the sandwich panels components.

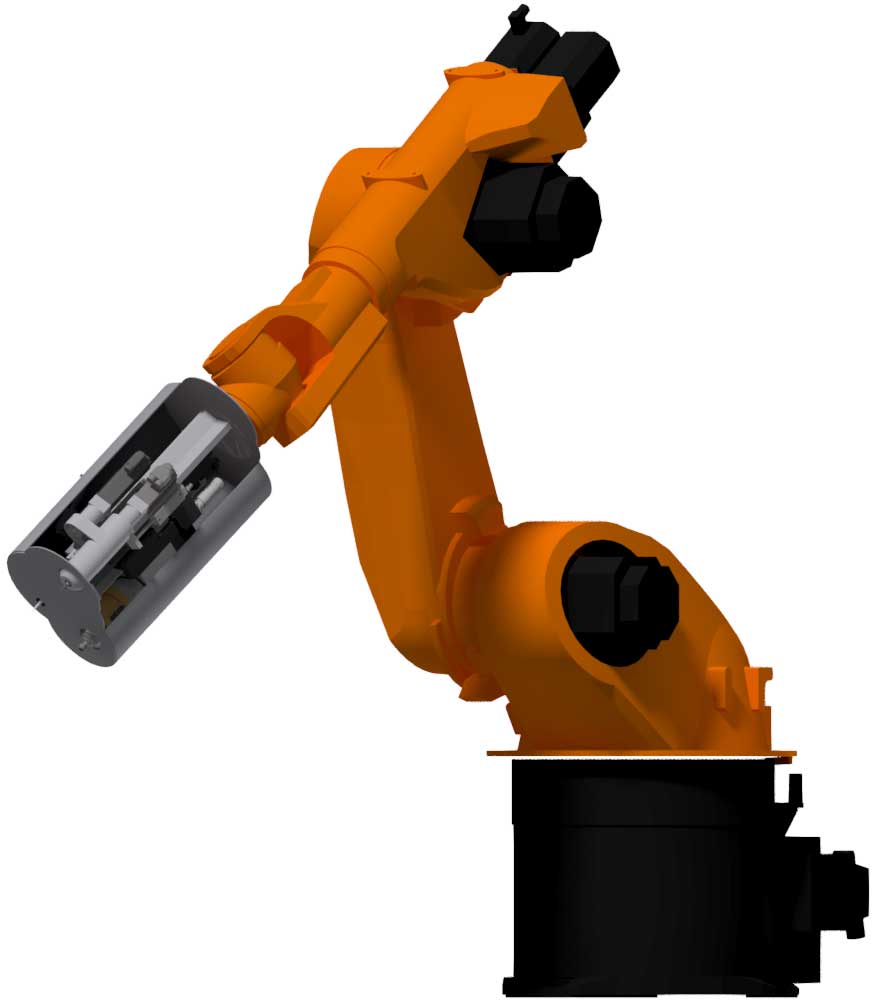

The fixing solution developped by SECAM and the robotization by GEBE2 is the best productive answer to these 2 problems.

Automated potted-in insert fixation for sandwich panels – SECAMnida®

- Drilling of the sandwich panel

- Crimping of the insert on the upper skin

- Injection of the two-components potting compound

- Filling control – no additional finishing operations

Advantages of robotics for potted-in insert fixing on honeycomb panel (nomex and alu).

Design

Simplified structures design

No extra reinforcement

Strong

Equivalent of higher mechanical strength in regards to standard

Light

Ligthen metal inserts

Overall weight reduction

Fast

Installation is 4 time quicker and requires 50% less steps compared to conventional methods

Costs killer

Descrease of production downtimes

Strong overall productivity gain

Simple

Immediate handling ofter crimping

No need for finishing operations

Objective

Offer to market manufacturers a robotized solution for potted-in inserts fixing on honeycomb sandwich panels

- fixing process time divided by 4

- two times less steps required compared to conventional process

SECAMnida® is a registered trademark of SECAM.