- Home

- >

- Composite and metallic finishing process

Robotic machining of composite and metallic materials

Robotic machining of composite and metallic materials

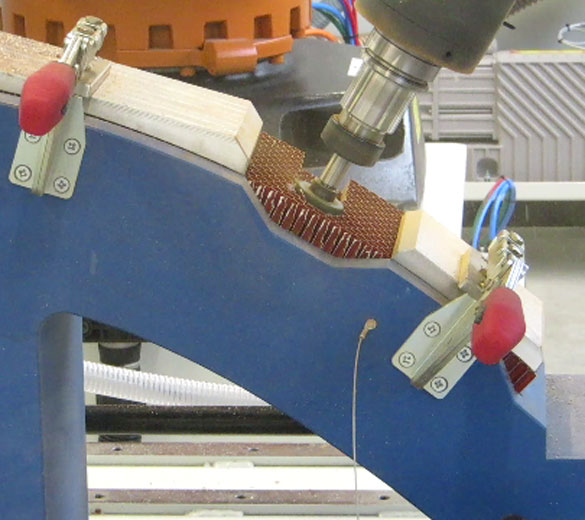

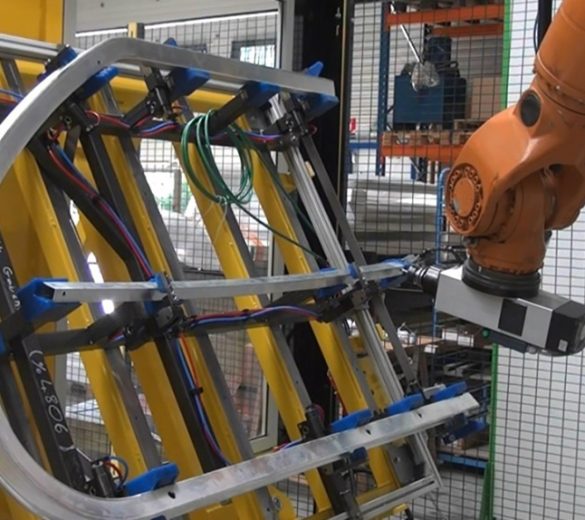

Integrator of robotized machining processes, GEBE2 provides machining and trimming solutions based on the use of 6-axis polyarticulated robots, motor spindles with or without liquid cooling, radio or wire probes, automatic tool change, standard machining software and mobile robots capable of extending their work envelope.

We also integrate the definition of tool centers, part reference guides and the use of Offline Programming software that programs, simulates and modifies trajectories based on CAD parts and the working environment.